Engine Starting and Engine Testing

Engine starting and testing with rectifiers is a critical process in various industries, especially in the automotive, aviation, marine, and power generation sectors. Rectifiers are electrical devices used to convert alternating current (AC) into direct current (DC), making them an essential component in engine starting and testing applications.

Engine Starting with Rectifiers:

In many industries, engines require a high surge of electrical power to start. This is particularly true for large engines in heavy machinery, ships, and power plants. Rectifiers play a crucial role in providing the necessary DC power for engine starting. They convert the AC power from the electrical grid or other power sources into a high-current DC output to crank the engine and initiate the combustion process.

Rectifiers used for engine starting are designed to handle high currents and deliver the necessary power in a short burst. They must be reliable and capable of providing instantaneous power to ensure smooth engine starting, even in adverse conditions.

Engine Testing with Rectifiers:

Testing engines is an essential part of their development and maintenance. Whether it’s testing newly manufactured engines or conducting regular performance assessments, rectifiers play a vital role in providing precise and controlled electrical power for engine testing.

In engine testing applications, rectifiers provide the required DC power to simulate various operational conditions. The power supply needs to be stable and adjustable, allowing engineers to recreate different load scenarios and test the engine’s performance under different conditions.

Have a question about Engine Starting & Testing?

Advantages of Using Rectifiers for Engine Starting and Testing:

1. Instantaneous Power: Rectifiers offer the advantage of providing high-current, direct power on-demand for engine starting, ensuring reliable and quick ignition.

2. Precise Control: In engine testing, rectifiers offer precise control over the output voltage and current, allowing engineers to simulate a wide range of operating conditions.

3. High Reliability: Rectifiers used for engine starting and testing are engineered for robustness and reliability, ensuring continuous and efficient operation.

4. Cost-Effective: Utilizing rectifiers for engine starting and testing can be more cost-effective and efficient than other power supply solutions.

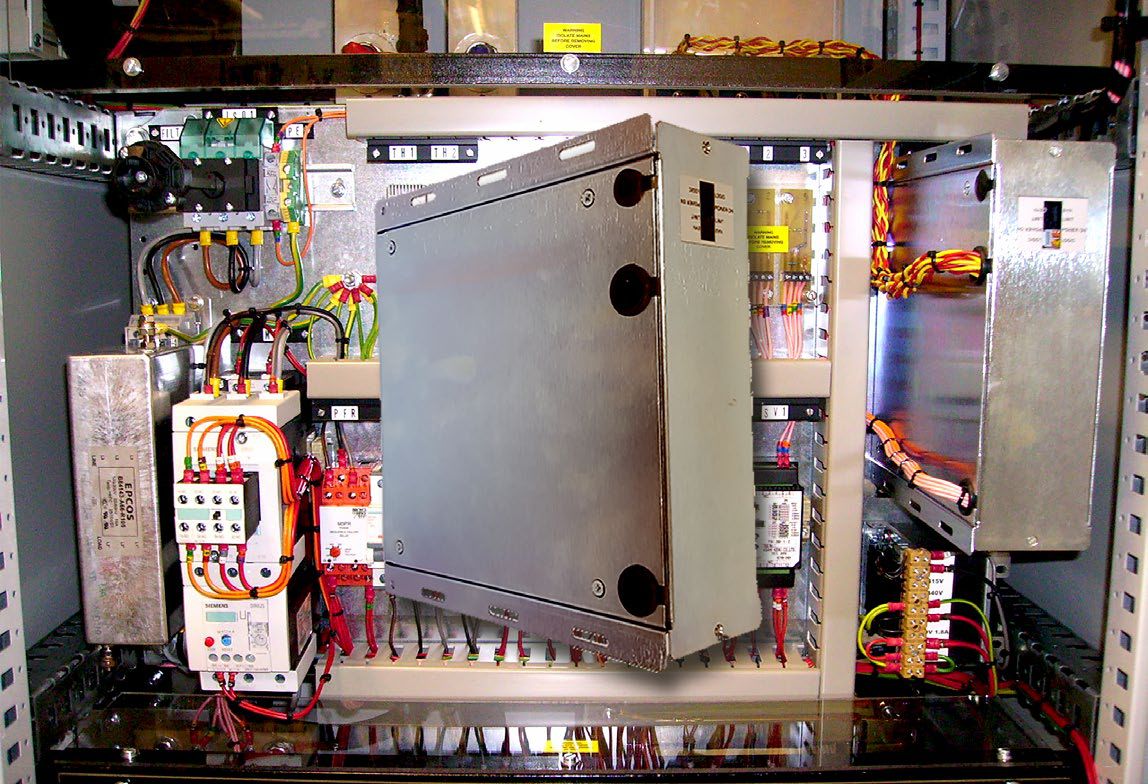

Powerstax: Empowering Engine Starting and Testing with Precision Power Solutions

At Powerstax, we take pride in offering cutting-edge power supply solutions specifically tailored for Engine Starting and Testing applications. With our unwavering commitment to innovation and decades of expertise in power technology, we empower industries to achieve flawless engine ignition and precise performance assessment with confidence.

Engine Starting Solutions – Propelling Success with Precision:

Powerstax’s Engine Starting rectifiers are engineered to deliver instantaneous power with unparalleled precision. Our products provide high-current, direct power on-demand, ensuring reliable ignition for engines of all sizes. With customizable current and voltage controls, we offer precise adjustment capabilities to match your unique engine requirements.

Engine Testing Solutions – Unleashing Performance Potential:

Accurate engine testing demands precise control, and Powerstax’s Engine Testing rectifiers rise to the occasion. With exceptional stability and adjustable output capabilities, our solutions empower engineers to simulate a broad range of operational conditions and evaluate engine performance with the utmost precision.

Key Features:

Stable, Robust, and Reliable: Powerstax Engine Starting and Testing rectifiers are designed for high peak currents, exceeding 200% of the operational (nominal) rated output current, ensuring flawless engine ignition in all conditions. Engine Testing rectifiers offer stable output power, ensuring consistent and repeatable test results for comprehensive performance assessments.

Fast Response: With rapid power delivery, our rectifiers allow quick engine starting, minimizing downtime, and enhancing productivity in critical operations.

Adjustable Power: Our rectifiers provide flexible current and voltage controls, allowing you to fine-tune the starting and testing process for optimal performance.

Why Choose Powerstax?

Customized Solutions: At Powerstax, we understand that every engine application is unique. Our expert team collaborates closely with you to design tailored power supply solutions that precisely match your needs.

Unwavering Reliability: Powerstax’s rectifiers are engineered for robustness and durability, ensuring consistent operation and minimum downtime in critical applications.

Proven Expertise: With over five decades of experience in power supply technology, Powerstax has established itself as a trusted partner in the industry, delivering solutions that exceed expectations.

Unleash the Full Potential of Your Engines with Powerstax:

Whether you require precise engine starting or comprehensive performance testing, Powerstax offers the power and control you need. Our Engine Starting and Testing solutions empower you to optimize engine starting and performance assessment, driving success in diverse industries, such as naval, high-end industrial, etc.

Contact us today and let Powerstax be the driving force behind your engine’s triumph. Together, we elevate the art of engine starting and testing, delivering excellence, reliability, and precision in every application. Power your engines with Powerstax – Unleashing Performance, Propelling Success.

Have a question about Engine Starting & Testing?

Application Categories

Showing 0–0 of 0 results