The Cathodic Protection Process:

Cathodic protection is a corrosion prevention technique used to protect metal structures and surfaces from deterioration caused by electrochemical reactions. Corrosion occurs when metal surfaces come into contact with corrosive environments, such as moisture, saltwater, or certain chemicals, resulting in the breakdown of the metal and eventual damage or failure.

Cathodic protection works by making the metal structure or surface the cathode of an electrochemical cell, thereby reducing its corrosion rate. It achieves this by introducing an external electrical current to counteract the natural corrosion process. There are two primary types of cathodic protection:

Sacrificial Cathodic Protection: In this method, sacrificial anodes made of a more reactive metal, such as zinc or magnesium, are connected to the metal structure to be protected. When the corrosive environment attacks the metal, the sacrificial anodes corrode sacrificially instead, releasing electrons that neutralize the electrochemical reactions at the protected metal surface.

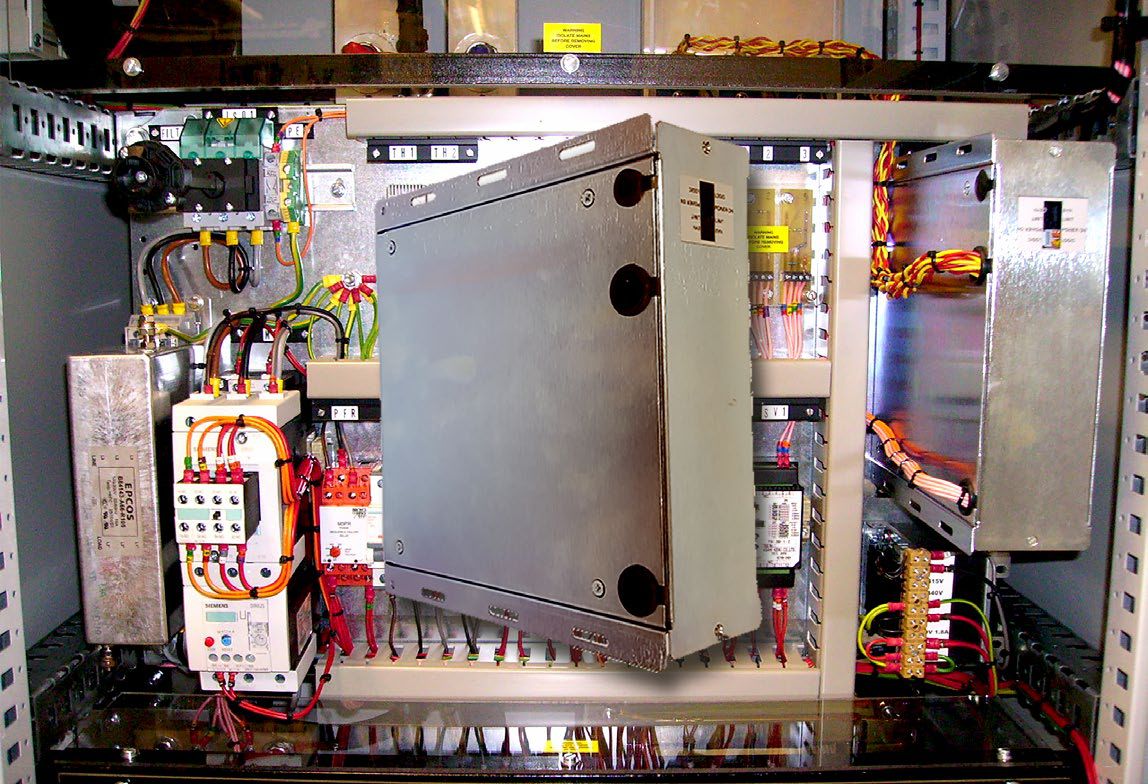

Impressed Current Cathodic Protection: This method involves using an external power source, such as a rectifier, to provide a controlled electrical current to the metal structure. The current is directed towards the structure, making it the cathode, and slowing down the corrosion process. This system typically uses inert anodes, such as titanium or mixed metal oxide (MMO) anodes, which do not corrode.

Cathodic protection is commonly employed to protect a wide range of metal structures, including pipelines, underground storage tanks, offshore platforms, ship hulls, piers, and steel-reinforced concrete structures. It is particularly beneficial in environments where corrosion rates are high, such as in marine environments or industrial facilities.

Have a question about Cathodic Protection?

By implementing cathodic protection, industries can extend the lifespan of metal assets, reduce maintenance costs, and enhance safety and environmental protection. The choice between sacrificial and impressed current cathodic protection depends on factors such as the size of the structure, the corrosive environment, and the desired level of protection.

Overall, cathodic protection is a crucial and effective corrosion prevention technique that helps preserve the integrity and longevity of metal structures, ensuring their reliability and safety in various industries and applications.

Empowering Cathodic Protection with Powerstax Solutions

Powerstax is at the forefront of corrosion prevention technology, offering advanced solutions for Impressed Current Cathodic Protection. With our expertise in power supply technology and a strong commitment to innovation, Powerstax is your trusted partner in safeguarding metal structures and surfaces from the damaging effects of corrosion.

Taking Control of Corrosion

Corrosion poses a significant threat to metal structures in harsh environments, such as marine, industrial, and civil infrastructure settings. Powerstax’s Impressed Current Cathodic Protection solutions give you full control over corrosion, ensuring the longevity and integrity of your valuable assets.

Customized Protection for Diverse Applications

At Powerstax, we understand that each cathodic protection application is unique. Our expert team works closely with you to design custom power supply solutions tailored to your specific requirements. Whether you need protection for wind farms, oil platforms, tanks, vessels, pipelines, or other metallic structures, Powerstax delivers tailored solutions for reliable and efficient corrosion prevention.

Remote Monitoring for Enhanced Efficiency

Our cutting-edge power supply products allow remote monitoring and control, enabling you to stay connected to your cathodic protection systems from anywhere. Real-time monitoring ensures timely responses to changing conditions and allows you to make data-driven decisions for optimal performance.

Unleashing the Power of Cathodic Protection

Powerstax’s impressed current cathodic protection systems incorporate high-quality components and advanced features, ensuring precise and effective protection against corrosion. With our solutions, you harness the full power of cathodic protection, extending the lifespan of your assets and minimizing maintenance costs.

A Trusted Partner for Corrosion Prevention

Countless industries rely on Powerstax’s cathodic protection solutions to safeguard their critical assets. From offshore installations to onshore infrastructure, our products provide robust and dependable protection in diverse applications.

Safeguard Your Assets with Powerstax

Join the ranks of industry leaders who have embraced the power of cathodic protection with Powerstax solutions. Protect your metal structures and surfaces with confidence, knowing that our customized solutions and remote monitoring capabilities ensure unparalleled corrosion prevention.

Contact us today and let Powerstax empower your cathodic protection efforts. Together, we create a corrosion-resistant world, preserving the longevity and value of your valuable assets. Power your cathodic protection with Powerstax – Empowering Corrosion Prevention for a Stronger Future.

Have a question about Cathodic Protection?

Application Categories

Showing 0–0 of 0 results