Engine Starting & Testing

Engine Starting and Engine Testing

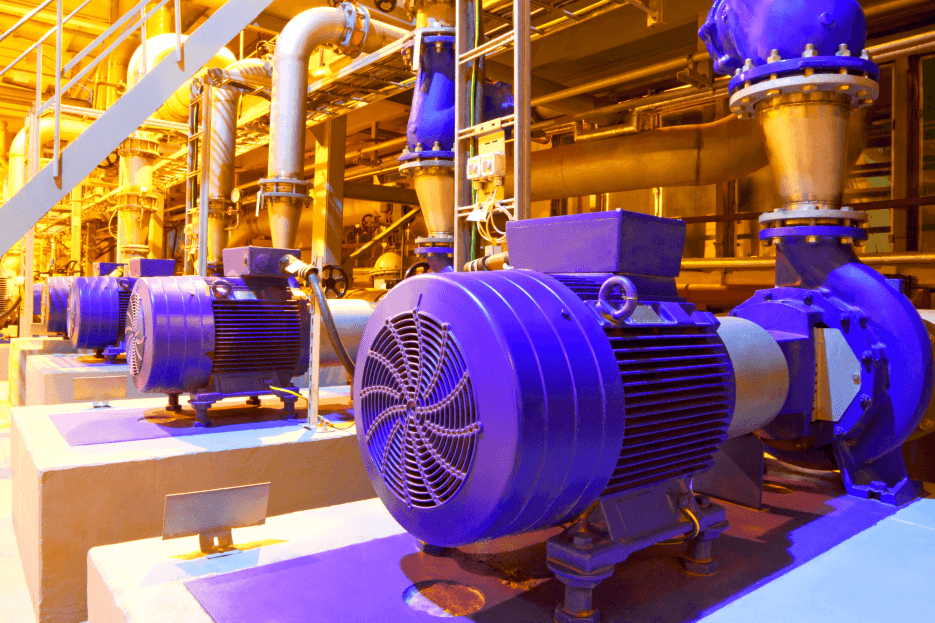

Engine starting and testing with rectifiers is a critical process in various industries, especially in the automotive, aviation, marine, and power generation sectors. Rectifiers are electrical devices used to convert alternating current (AC) into direct current (DC), making them an essential component in engine starting and testing applications.

Engine Starting with Rectifiers:

In many industries, engines require a high surge of electrical power to start. This is particularly true for large engines in heavy machinery, ships, and power plants. Rectifiers play a crucial role in providing the necessary DC power for engine starting. They convert the AC power from the electrical grid or other power sources into a high-current DC output to crank the engine and initiate the combustion process.

Rectifiers used for engine starting are designed to handle high currents and deliver the necessary power in a short burst. They must be reliable and capable of providing instantaneous power to ensure smooth engine starting, even in adverse conditions.

Engine Testing with Rectifiers:

Testing engines is an essential part of their development and maintenance. Whether it’s testing newly manufactured engines or conducting regular performance assessments, rectifiers play a vital role in providing precise and controlled electrical power for engine testing.

In engine testing applications, rectifiers provide the required DC power to simulate various operational conditions. The power supply needs to be stable and adjustable, allowing engineers to recreate different load scenarios and test the engine’s performance under different conditions.

Have a question about Engine Starting & Testing?

Advantages of Using Rectifiers for Engine Starting and Testing:

1. Instantaneous Power: Rectifiers offer the advantage of providing high-current, direct power on-demand for engine starting, ensuring reliable and quick ignition.

2. Precise Control: In engine testing, rectifiers offer precise control over the output voltage and current, allowing engineers to simulate a wide range of operating conditions.

3. High Reliability: Rectifiers used for engine starting and testing are engineered for robustness and reliability, ensuring continuous and efficient operation.

4. Cost-Effective: Utilizing rectifiers for engine starting and testing can be more cost-effective and efficient than other power supply solutions.

Powerstax: Empowering Engine Starting and Testing with Precision Power Solutions

At Powerstax, we take pride in offering cutting-edge power supply solutions specifically tailored for Engine Starting and Testing applications. With our unwavering commitment to innovation and decades of expertise in power technology, we empower industries to achieve flawless engine ignition and precise performance assessment with confidence.

Engine Starting Solutions – Propelling Success with Precision:

Powerstax’s Engine Starting rectifiers are engineered to deliver instantaneous power with unparalleled precision. Our products provide high-current, direct power on-demand, ensuring reliable ignition for engines of all sizes. With customizable current and voltage controls, we offer precise adjustment capabilities to match your unique engine requirements.

Engine Testing Solutions – Unleashing Performance Potential:

Accurate engine testing demands precise control, and Powerstax’s Engine Testing rectifiers rise to the occasion. With exceptional stability and adjustable output capabilities, our solutions empower engineers to simulate a broad range of operational conditions and evaluate engine performance with the utmost precision.

Key Features:

Stable, Robust, and Reliable: Powerstax Engine Starting and Testing rectifiers are designed for high peak currents, exceeding 200% of the operational (nominal) rated output current, ensuring flawless engine ignition in all conditions. Engine Testing rectifiers offer stable output power, ensuring consistent and repeatable test results for comprehensive performance assessments.

Fast Response: With rapid power delivery, our rectifiers allow quick engine starting, minimizing downtime, and enhancing productivity in critical operations.

Adjustable Power: Our rectifiers provide flexible current and voltage controls, allowing you to fine-tune the starting and testing process for optimal performance.

Why Choose Powerstax?

Customized Solutions: At Powerstax, we understand that every engine application is unique. Our expert team collaborates closely with you to design tailored power supply solutions that precisely match your needs.

Unwavering Reliability: Powerstax’s rectifiers are engineered for robustness and durability, ensuring consistent operation and minimum downtime in critical applications.

Proven Expertise: With over five decades of experience in power supply technology, Powerstax has established itself as a trusted partner in the industry, delivering solutions that exceed expectations.

Unleash the Full Potential of Your Engines with Powerstax:

Whether you require precise engine starting or comprehensive performance testing, Powerstax offers the power and control you need. Our Engine Starting and Testing solutions empower you to optimize engine starting and performance assessment, driving success in diverse industries, such as naval, high-end industrial, etc.

Contact us today and let Powerstax be the driving force behind your engine’s triumph. Together, we elevate the art of engine starting and testing, delivering excellence, reliability, and precision in every application. Power your engines with Powerstax – Unleashing Performance, Propelling Success.

Have a question about Engine Starting & Testing?

Application Categories

Showing 0–0 of 0 results

Cathodic Protection

The Cathodic Protection Process:

Cathodic protection is a corrosion prevention technique used to protect metal structures and surfaces from deterioration caused by electrochemical reactions. Corrosion occurs when metal surfaces come into contact with corrosive environments, such as moisture, saltwater, or certain chemicals, resulting in the breakdown of the metal and eventual damage or failure.

Cathodic protection works by making the metal structure or surface the cathode of an electrochemical cell, thereby reducing its corrosion rate. It achieves this by introducing an external electrical current to counteract the natural corrosion process. There are two primary types of cathodic protection:

Sacrificial Cathodic Protection: In this method, sacrificial anodes made of a more reactive metal, such as zinc or magnesium, are connected to the metal structure to be protected. When the corrosive environment attacks the metal, the sacrificial anodes corrode sacrificially instead, releasing electrons that neutralize the electrochemical reactions at the protected metal surface.

Impressed Current Cathodic Protection: This method involves using an external power source, such as a rectifier, to provide a controlled electrical current to the metal structure. The current is directed towards the structure, making it the cathode, and slowing down the corrosion process. This system typically uses inert anodes, such as titanium or mixed metal oxide (MMO) anodes, which do not corrode.

Cathodic protection is commonly employed to protect a wide range of metal structures, including pipelines, underground storage tanks, offshore platforms, ship hulls, piers, and steel-reinforced concrete structures. It is particularly beneficial in environments where corrosion rates are high, such as in marine environments or industrial facilities.

Have a question about Cathodic Protection?

By implementing cathodic protection, industries can extend the lifespan of metal assets, reduce maintenance costs, and enhance safety and environmental protection. The choice between sacrificial and impressed current cathodic protection depends on factors such as the size of the structure, the corrosive environment, and the desired level of protection.

Overall, cathodic protection is a crucial and effective corrosion prevention technique that helps preserve the integrity and longevity of metal structures, ensuring their reliability and safety in various industries and applications.

Empowering Cathodic Protection with Powerstax Solutions

Powerstax is at the forefront of corrosion prevention technology, offering advanced solutions for Impressed Current Cathodic Protection. With our expertise in power supply technology and a strong commitment to innovation, Powerstax is your trusted partner in safeguarding metal structures and surfaces from the damaging effects of corrosion.

Taking Control of Corrosion

Corrosion poses a significant threat to metal structures in harsh environments, such as marine, industrial, and civil infrastructure settings. Powerstax’s Impressed Current Cathodic Protection solutions give you full control over corrosion, ensuring the longevity and integrity of your valuable assets.

Customized Protection for Diverse Applications

At Powerstax, we understand that each cathodic protection application is unique. Our expert team works closely with you to design custom power supply solutions tailored to your specific requirements. Whether you need protection for wind farms, oil platforms, tanks, vessels, pipelines, or other metallic structures, Powerstax delivers tailored solutions for reliable and efficient corrosion prevention.

Remote Monitoring for Enhanced Efficiency

Our cutting-edge power supply products allow remote monitoring and control, enabling you to stay connected to your cathodic protection systems from anywhere. Real-time monitoring ensures timely responses to changing conditions and allows you to make data-driven decisions for optimal performance.

Unleashing the Power of Cathodic Protection

Powerstax’s impressed current cathodic protection systems incorporate high-quality components and advanced features, ensuring precise and effective protection against corrosion. With our solutions, you harness the full power of cathodic protection, extending the lifespan of your assets and minimizing maintenance costs.

A Trusted Partner for Corrosion Prevention

Countless industries rely on Powerstax’s cathodic protection solutions to safeguard their critical assets. From offshore installations to onshore infrastructure, our products provide robust and dependable protection in diverse applications.

Safeguard Your Assets with Powerstax

Join the ranks of industry leaders who have embraced the power of cathodic protection with Powerstax solutions. Protect your metal structures and surfaces with confidence, knowing that our customized solutions and remote monitoring capabilities ensure unparalleled corrosion prevention.

Contact us today and let Powerstax empower your cathodic protection efforts. Together, we create a corrosion-resistant world, preserving the longevity and value of your valuable assets. Power your cathodic protection with Powerstax – Empowering Corrosion Prevention for a Stronger Future.

Have a question about Cathodic Protection?

Application Categories

Showing 0–0 of 0 results

Electrochlorination

Empowering Effective Water Treatment with Powerstax Electrochlorination Solutions

Powerstax proudly presents cutting-edge power supply solutions specifically tailored for water treatment applications, with a particular focus on electrochlorination processes. As a trusted partner in sustainability and environmental preservation, we offer a range of high-efficiency and reliable power supplies designed to optimize the electrochlorination process, ensuring safe and effective water treatment for both in-land and marine applications.

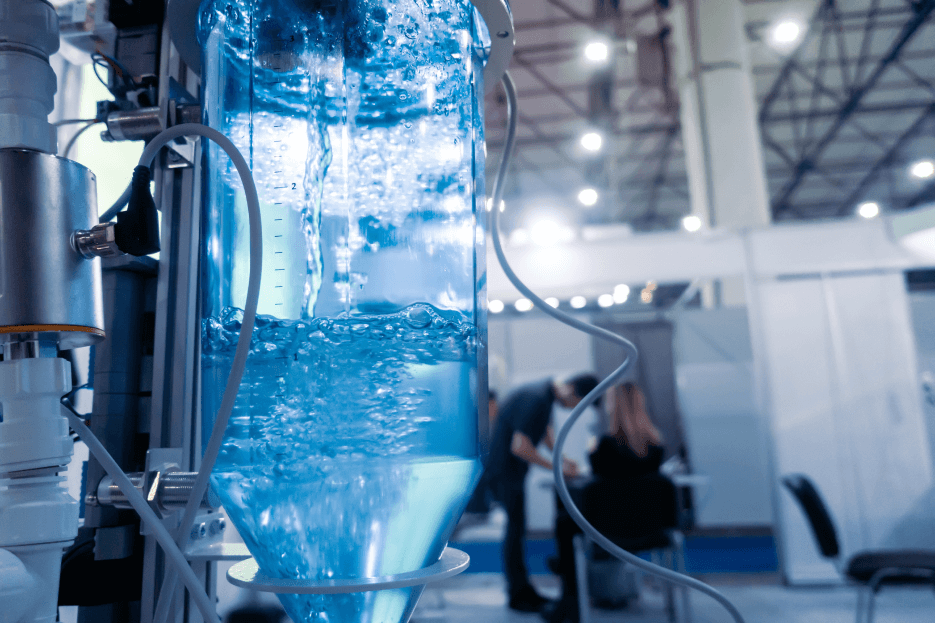

The Power of Electrochlorination

Electrochlorination is a powerful water treatment process that leverages the production of chlorine and other powerful disinfectants through electrolysis. This innovative method provides a safer, greener, and more cost-effective approach to maintaining water quality, protecting ecosystems, and complying with stringent environmental regulations.

Powerstax’s Electrochlorination Solutions

At Powerstax, we recognize the significance of water treatment in preserving the planet’s most vital resource. Our versatile power supply solutions, featuring advanced series such as DPTR, Powerkraft, Flexkraft, ECKraft, and Unistax, have been engineered to empower the electrochlorination process with unmatched precision and efficiency while providing you with clean water for drinking and utilizing on your daily life.

Have a question about Electrochlorination?

Efficiency and Stability for Water Quality

Our power supplies boast high-efficiency designs, delivering stable and precise electrical power required for optimal electrolysis in the chlorination process. By generating chlorine on-site, our solutions eliminate the need for transportation and storage of hazardous chemicals, ensuring safer and more sustainable water treatment practices.

Reliability for Critical Applications

Water treatment is a mission-critical process, and Powerstax’s commitment to reliability is unwavering. Our power supplies are designed and tested to withstand the most demanding environments, ensuring continuous operation, and minimizing downtime. With Powerstax solutions, you can trust that your water treatment operations are in safe and capable hands.

Compliance with Stringent Regulations

For ship ballast applications, our power supplies help vessels meet international ballast water treatment regulations, safeguarding marine ecosystems from the spread of invasive species. Powerstax empowers ship operators to adopt green and compliant solutions, fostering environmental stewardship within the maritime industry.

A Sustainable Path Forward

As a responsible leader in the power supply industry, Powerstax believes in providing sustainable solutions that contribute to a cleaner and healthier planet. Our electrochlorination solutions epitomize this commitment, offering a green and efficient approach to water treatment that aligns with global efforts towards sustainability.

Have a question about Electrochlorination?

Application Categories

Showing 0–0 of 0 results

Other Electrolysis

Unlocking the Potential of Electrolysis with Powerstax Solutions

Powerstax proudly presents a versatile range of power supply solutions that transcend industries and applications, all centered around the transformative power of electrolysis. Our products, already proven effective in carbon capture and green hydrogen production, now find new applications in water treatment and surface finishing through electrolysis.

Series DPTR, Powerkraft, Flexkraft, ECKraft, Unistax – Powering the Future of Electrolysis

Powerstax understands the diverse applications of electrolysis and how crucial this technology is in addressing global challenges. Our series of cutting-edge power supplies, including DPTR, Powerkraft, Flexkraft, ECKraft, and Unistax, are not limited to specific industries; instead, they power a wide array of electrolysis-related processes, ensuring maximum efficiency and reliability.

Efficiency and Reliability for Water Treatment

Water treatment is essential for both in-land and marine applications, and Powerstax’s power supplies play a pivotal role in electro-chlorination processes. With our high-efficiency designs, we provide the stable and precise electrical power needed to produce chlorine and other chemicals essential for effective water treatment. Powerstax’s commitment to reliability ensures consistent performance, making a positive impact on water quality and environmental preservation.

Have a question about Electrolysis?

Green Solutions for Ship Ballast Electro-chlorination

For ship ballast applications, Powerstax’s power supplies offer green and sustainable solutions to maintain ballast water quality. Our electrolysis-related products facilitate electro-chlorination processes, safeguarding marine ecosystems and complying with international ballast water treatment regulations. Powerstax empowers ship operators to enhance environmental stewardship while ensuring the smooth operation of their vessels.

Enhancing Surface Finishing through Electrolysis

Beyond environmental applications, Powerstax’s power supplies find use in surface finishing, where electrolysis plays a crucial role in plating and electroplating processes. With our series of adaptable and versatile power supplies, we provide the precise electrical control needed to achieve high-quality surface finishes in diverse industries. From electronics to automotive, our solutions elevate the standards of surface treatment processes.

Your Trusted Partner in Electrolysis Solutions

At Powerstax, we take pride in our expertise in electrolysis-related applications, enabling a wide range of industries to harness the power of this transformative process. From carbon capture and green hydrogen production to water treatment and surface finishing, our power supplies stand as a cornerstone of efficiency, reliability, and sustainability.

Choose Powerstax as your trusted partner in unlocking the full potential of electrolysis for your organization. Our experienced team is ready to provide customized solutions, seamless integration, and comprehensive support, empowering you to lead in a world driven by the power of technology. Together, let’s revolutionize industries, preserve the environment, and build a brighter and sustainable future. Contact us today and let Powerstax power your path to success.

Have a question about Electrolysis?

Application Categories

Showing 0–0 of 0 results

Hydrogen Production

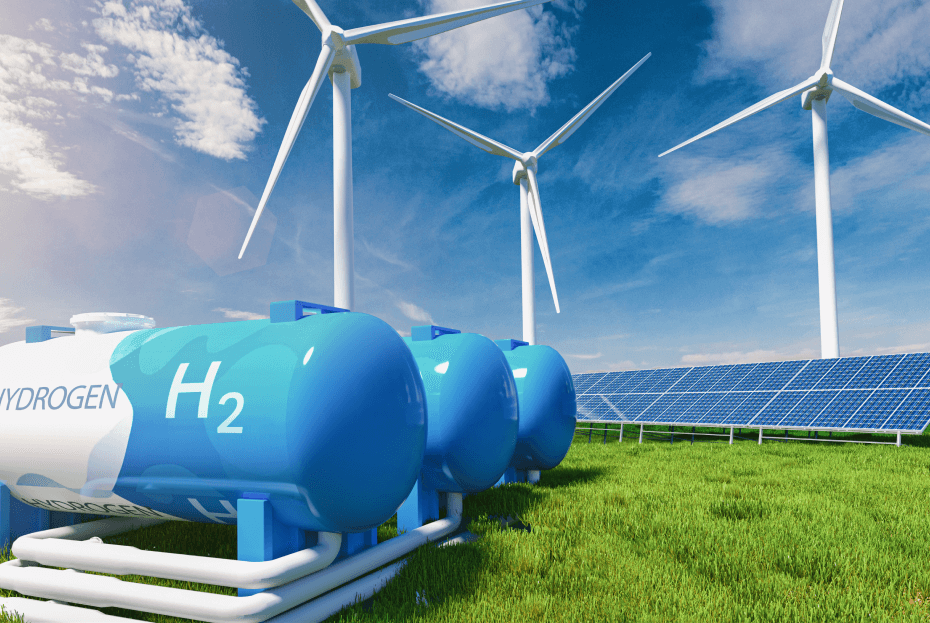

Powerstax: Your Trusted Partner for Hydrogen Production Power Supplies

With decades of experience in Thyristor-Controlled Transformer Rectifiers (TRs) and other types of power supply units (PSUs), such as Switched Mode Power Supplies, including IGBT (Insulated-Gate Bipolar Transistor) technologies, we stand as a reliable and knowledgeable partner for your hydrogen production needs.

Powerstax has a wealth of experience when it comes to Hydrogen Production, being active on this emerging market, which is called Green Hydrogen Production, that basically consists of the utilization of green energy sources (renewable, such as solar, wind, tidal, etc.) to power up electrolysis cells.

We have been supporting customers over the years that are both in the research and production stages. From startups to consolidated companies, we are able to add value to a big range of customers.

Green Hydrogen Production with Powerstax Power Supplies

Powerstax has a wealth of experience when it comes to Hydrogen Production, being active on this emerging market, which is called Green Hydrogen Production, that basically consists of the utilization of green energy sources (renewable, such as solar, wind, tidal, etc.) to power up electrolysis cells.

We have been supporting customers over the years that are both in the research and production stages. From startups to consolidated companies, we are able to add value to a big range of customers.

Have a question about Hydrogen Production?

Tailored Solutions for Optimal Performance

We understand that every hydrogen production application is unique, and that’s why we take a tailored approach to meet your specific requirements. Our team of experts works closely with you to customize solutions that perfectly match your needs, ensuring optimal performance and efficiency.

From Low to High Power Demands

Whether you require low power solutions of just a few kilowatts or high-power solutions in the multi-megawatt range, Powerstax has you covered. Our extensive product portfolio can accommodate a wide spectrum of power demands, allowing you to scale your hydrogen production operations as needed.

World-Class Support at Every Step

At Powerstax, our commitment to customer satisfaction extends beyond product delivery. We offer first-class worldwide support throughout your entire journey:

Pre-Sales Support: Our knowledgeable team is ready to assist you in selecting the ideal power supply solution for your hydrogen production application. We provide detailed technical consultations and recommendations to ensure the right fit.

Post-Sales Assistance: Once you choose Powerstax, our support doesn’t end with the sale. Our dedicated post-sales team is here to provide ongoing assistance, addressing any questions or concerns you may have.

Consultative Approach: We believe in forging strong partnerships with our customers, and our consultative approach ensures that we understand your unique needs and deliver solutions that exceed your expectations.

Servicing: Count on us for reliable servicing and maintenance support, ensuring your power supplies continue to perform at their best, reducing downtime and maximizing productivity.

Trust Powerstax for Hydrogen Production Power Supplies

When it comes to powering your electrolysers and producing hydrogen efficiently and reliably, Powerstax stands as your trusted partner. Benefit from our decades of experience, tailor-made solutions, and world-class support to elevate your hydrogen production operations. Contact us today and let us empower your success in the hydrogen industry with cutting-edge power supply solutions.

Have a question about Hydrogen Production?

Application Categories

Showing 0–0 of 0 results